Key Benefits of using Lite3D

3D data for all users

Establishing 3D as a common collaboration language with less discussion and misunderstandings compared to 2D.

Reduce cost and complexity of CAD based processes

Relying on industry proven, lightweight, neutral formats such as JT and STEP saves expensive CAD licenses.

View 3D models on any device.

Due to its slim format, 3D data can be easily accessed from mobile devices such as smartphones or tablets.

Use LiteBox3D Web viewer or Export models as HTML web page for viewing in a web browser.

Use Plug-ins

Add plug-ins to extend viewer capabilities. For example, for checking data quality or comparing models.

Lite3D Product Portfolio

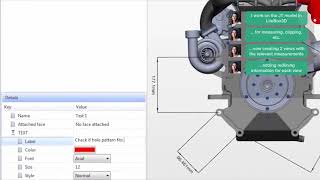

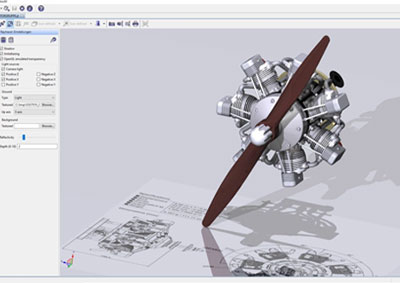

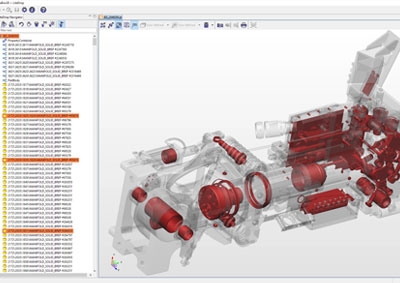

LiteBox3D Desktop Viewer

LiteBox3D Desktop is a powerful and free to use viewer, which supports multiple neutral 2D and 3D formats such as: JT ISO standard, PLMXML, STEP AP242, OBJ, WRL and TIFF.

This viewer can be expanded with add-on applications for IP protection, model comparison and quality validation.

The Pro version extends the capabilities of the free viewer with features such as redlining, 3DHTML export and more.

LiteBox3D Web Viewer

LiteBox3D Web Viewer is a user-friendly JT viewer based on HTML5. 3D data can be displayed in any browser and on any device.

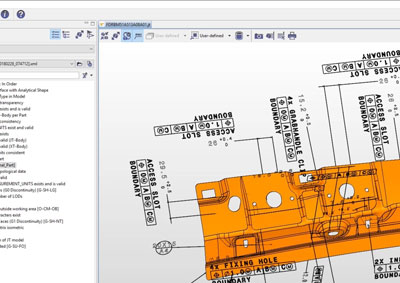

LiteComply

LiteComply is a compliance tool that checks whether JT models conform with the development guidelines of a customer in the area of geometry, structure and methodology, and meet both legal regulations and the requirements for subsequent processes.

LiteDrop

LiteDrop enables easy management of the content of JT files to increase viewing performance and protecting your IP.

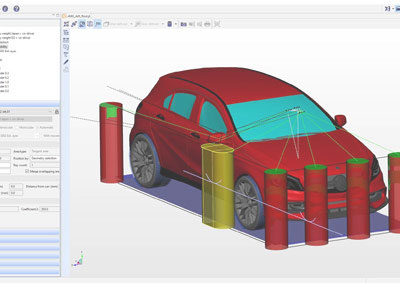

LiteCar

When developing new vehicles, standards, guidelines and norms from different countries must be taken into account. LiteCar ensures the legal compliance of the vehicle architecture during the construction phase. Typical international standards such as GTR or Euro NCAP are available and individual, company-specific standards can be integrated.

Lite3D Batch Tools

LiteSilhouette

The batch tool calculates silhouettes of 3D geometry in a given viewing plane. The calculated silhouette points are stored in an XML-based output file.

An input file specifies the file, vectors for the plane, and the accuracy of the silhouette.

The result is an XML file containing the enclosed surface area value, a list of point coordinates, a list of indices for all points on the outer and inner contours, as well as a list of indices for all points of the tessellation.

LiteBoundingBox

The command-line tool LiteBoundingBox.exe calculates the size of the bounding box of JT models. The result is outputted in an XML file. Both monolithic and fully shattered (modular) models can be processed.

The output file is in XML format and includes values for the bounding box in the X, Y, and Z directions. The local coordinate system of the model serves as a reference.

LiteProperties

The command-line tool LiteProperties.exe allows the addition, modification, and deletion of properties in a JT model.

The desired changes are defined in an XML file, which is then processed by LiteProperties. In this configuration file, any number of properties can be specified for creation, modification, or deletion.

Lite3DHTML

3DHTML is a proprietary format by TECHNIA, encapsulating the tessellated representation, the structural tree, PMIs (Product Manufacturing Information), and metadata of a 3D model within an HTML document.

Using the command-line tool Lite3DHTML.exe, you can export a 3D model as an HTML document. This HTML document can be visualized in browsers that support WebGL.

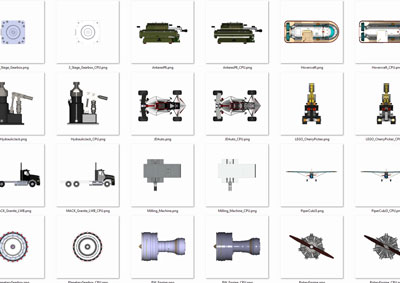

LiteImage

LiteImage allows the generation of images from JT models and assemblies (PLMXML, STEP AP242 XML), saving them as PNG files. This lightweight tool is operated through the command line and can be utilized in various ways, such as triggered externally, in a daily batch run, upon loading a 3D model, etc.

- LiteImage adheres to these predefined settings:

- Shaded representation with edges

- Transparent background

- Disabled highlights