What is Modeling and Simulation (MODSIM)?

Table of contents

- MODSIM, or Modeling and Simulation

- Why Use Simulation Early on in Product Development?

- What Does MODSIM Offer?

- Improve Collaboration

- Quickly Update Designs

- Cut Prototyping Costs

- Increase Overall Efficiency

- Who Benefits from Modeling and Simulation?

- Why is MODSIM More Relevant Today Than Ever Before?

- Why Choose MODSIM with 3DEXPERIENCE?

- In Our Experience…

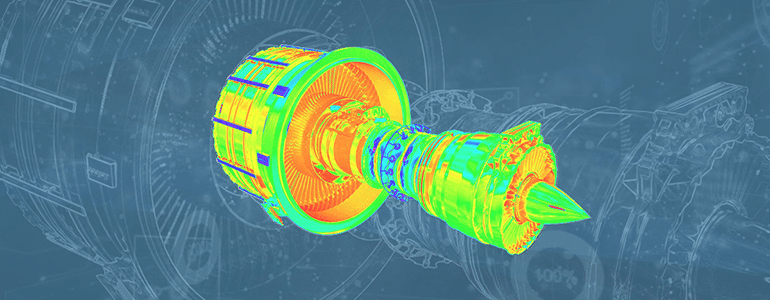

MODSIM, or Modeling and Simulation

This might not be a term that everyone relates to. So, let’s break it down to its core to understand more.

The average design process starts with 3D CAD Modeling performed by Design Engineers. The aim is to create a model which satisfies all design criteria before passing the design on to Simulation Engineers for validation. This process goes back and forth until all design criteria are met.

However, if you combine the design and simulation functions seamlessly together, you can leverage a whole new exciting dynamic!

Allowing not only the design engineers’ ideas and skill to generate innovation but using simulation to also drive validated design innovation at the same time.

Design Engineers benefit from simulation informing, supporting, and validating design innovation on the fly. Your teams immediately save time and cut down on re-work while increasing their output quality.

Simply put, MODSIM is a data-driven, collaborative, and concurrent approach to product development.

Why Use Simulation Early on in Product Development?

The more complex a product is required to be, the easier it is to understand the benefits of simulation to the design development process. But modeling simulation isn’t just about understanding complex mechanics, stresses, and geometries.

MODSIM enables design teams to run through hundreds, even thousands of product options in a fraction of the time it would otherwise take. Plainly, organizations that take this approach are better equipped to create superior products and reach market sooner than their competitors.

What Does MODSIM Offer?

Among the top challenges OEMs face are achieving a faster time-to-market, accelerating innovation, and cutting costs. Modeling Simulation is a practice borne out of that understanding. Below are some ways in which MODSIM will help you to achieve those goals:

Improve Collaboration

Enable simulation experts and product developers to work together on modeling and faster simulations. Product designers are given more room to experiment, which stimulates innovation, as engineers’ work is better informed by simulation.

Quickly Update Designs

Particularly in the early stages of product development, using simulation to inform product design work enables your teams to identify and solve potential issues ahead of time.

Cut Prototyping Costs

Multiphysics simulation and analysis in early design phases help you to gain confidence in designs without the need for costly prototyping.

Increase Overall Efficiency

Ensure that less time is spent performing rework tasks by taking a more connected and collaborative approach to product development.

Who Benefits from Modeling and Simulation?

Modeling and Simulation (MODSIM) offers a wide range of benefits to various stakeholders across different industries. Here’s a breakdown of the roles, industries, and organizations that can benefit from MODSIM:

Engineers and Designers

- Design Engineers: MODSIM enables design engineers to create and validate 3D models in real-time, leading to more efficient and innovative designs.

- Simulation Engineers: Simulation experts benefit from integrated simulation tools, allowing them to analyze and optimize designs without switching between different software, thus saving time and improving accuracy.

Product Managers and Development Teams

- Product Managers: They gain access to real-time insights into the impact of design changes on performance, cost, and time-to-market. This helps in making informed decisions and setting clear project goals.

- Development Teams: MODSIM fosters collaboration between cross-functional teams, enhancing communication and accelerating product development.

Manufacturers

- Manufacturing Engineers: MODSIM aids in designing products that are easier to manufacture and assemble, reducing production costs and improving efficiency.

- Quality Control: By identifying potential issues early in the design phase, MODSIM helps in ensuring product quality and reducing defects during manufacturing.

Research and Development (R&D) Teams

- R&D Engineers: Benefit from MODSIM by conducting virtual experiments and exploring a wide range of design options quickly, saving time and resources in the innovation process.

Aerospace and Automotive Industries

- Aerospace Engineers: MODSIM is crucial for simulating complex aerodynamics and structural behaviors, ensuring the safety and performance of aircraft.

- Automotive Engineers: It aids in vehicle design, crash simulations, fuel efficiency improvements, and the development of autonomous driving technologies.

Healthcare and Medical Device Manufacturers

- Biomedical Engineers: MODSIM assists in modeling and simulating biological systems, medical devices, and drug interactions for research and development in the healthcare sector.

Architecture and Construction

- Architects and Civil Engineers: MODSIM is used for building information modeling (BIM), helping in designing and simulating construction projects to ensure safety and efficiency.

Energy and Environmental Industries

- Energy Engineers: MODSIM is valuable for optimizing energy systems, renewable energy projects, and environmental impact assessments.

- Environmental Scientists: They use MODSIM to model and simulate ecological systems and environmental processes.

Education and Training

- Students and Researchers: MODSIM provides a practical and hands-on learning experience for students and researchers in various fields, enhancing their understanding of complex systems.

Sustainability Initiatives

- Organizations striving for sustainability benefit from MODSIM by assessing the environmental impact of their products and processes and identifying areas for improvement.

Government and Regulatory Bodies

- These entities use MODSIM for safety assessments, regulatory compliance, and policy development in areas such as transportation, healthcare, and environmental protection.

Startups and Small Businesses

- Smaller organizations can leverage MODSIM to compete with larger competitors by streamlining their product development processes and reducing costs.

The benefits of modeling and simulation are widespread, extending to anyone involved in product development, research, innovation, and problem-solving. MODSIM empowers individuals and organizations to create better products, make informed decisions, and drive progress in their respective fields.

Why is MODSIM More Relevant Today Than Ever Before?

Simulation and analysis have long been essential tools for competitive manufacturers. They have distinguished organizations as true industry leaders. However, MODSIM represents a significant shift in product development practices. Simulation engineers are now relied upon more heavily for foundational analysis during product innovation and development. Continuous improvement has made simulation tools more accessible to design engineers.

Why Choose MODSIM with 3DEXPERIENCE?

Seamless Integration

The 3DEXPERIENCE platform offers a unified ecosystem where various aspects of product development, including 3D modeling, simulation, collaboration, and data management, seamlessly come together. This integration eliminates data silos and facilitates real-time collaboration between teams.

End-to-End Solution

The 3DEXPERIENCE platform provides a comprehensive suite of tools that cover the entire product development lifecycle. From ideation and design to simulation, testing, and manufacturing, it offers a complete solution under one roof.

Data-Driven Decision-Making

With the 3DEXPERIENCE platform, data becomes a driving force in decision-making. It allows you to make informed choices by providing real-time insights into how design changes impact performance and other critical factors. This data-driven approach is invaluable for creating optimized and competitive products.

Collaboration at Its Core

Collaboration is at the heart of the 3DEXPERIENCE platform. It enables cross-functional teams, including engineers, designers, simulation experts, and managers, to work together seamlessly. This collaborative environment fosters innovation and accelerates the development process.

Scalability

The platform is highly scalable, making it suitable for organizations of all sizes, from small startups to large enterprises. Whether you’re working on a single project or managing a complex product portfolio, the 3DEXPERIENCE platform can adapt to your needs.

Simulation Expertise

The platform offers robust simulation capabilities through Dassault Systèmes’ SIMULIA brand. SIMULIA is a renowned leader in simulation technology, known for its accuracy and depth of analysis. This expertise ensures that your simulation results are reliable and meaningful.

In Our Experience…

Simulation and analysis are nothing new to competitive manufacturers. But they are invaluable tools that have defined organizations as just that: competitive.

Modeling Simulation, or MODSIM, represents a meaningful shift in product development best practices. Simulation engineers are more heavily relied on for foundational analysis during product innovation and development processes. And continuous improvement has made simulation tools that much more accessible to design engineers. All with the aim of making better products, faster.

Discover how Modeling and Simulation can improve your product development process