Improve Your SOLIDWORKS Data Governance with PLM

Table of contents

Typical pain points with CAD data management include:

- Version control – Multiple versions, parallel work, old designs, compatible changes.

- Data organization – Large and complex structures, finding the correct data fast.

- Collaboration – Local stores, parallel work, communication related to designs.

- Security – Local copies, email deliveries, clean-up of local cached data.

- Integration – ERP, CRM, MES, BI, SCM… How can you automate controlled data flow?

If any of these points apply to your business, then this blog post is for you!

How Can PLM Improve SOLIDWORKS Data Governance?

PLM (Product Lifecycle Management) solutions enable design teams to create, manage, and share design data from a centralized location. This allows for greater collaboration, enabling access to the latest designs, better change communication, and tracking of project progress throughout teams. PLM also provides greater control over design changes, as changes are tracked and documented throughout the entire product lifecycle, improving data quality, and ensuring that all stakeholders have access to up-to-date information.

In this blog, we’ll explain how connecting your CAD system with PLM can give you ultimate control over your SOLIDWORKS data governance and how easy it is for the designer to use PLM directly through the CAD client. The post focuses on the connector for SOLIDWORKS and 3DEXPERIENCE, but the functionality is not limited to SOLIDWORKS.

So, what are the 5 common findings from our customers when using the PLM connector in production operations?

What is PLM, and How Does it Affect Data Governance?

PLM (Product Lifecycle Management) is a system and a process of managing the whole product lifecycle from concept through to repurposing.

Companies can manage product data, automate workflows, and collaborate throughout multiple geographies. The evolution of design data (CAD data) storage has gone from local drives to lightweight PDM (Product Data Management) systems, and the new normal is having a PLM system connected to CAD software. PLM software can then also be integrated into downstream systems such as ERP and CRM to enable an automated data flow throughout the product lifecycle.

Why Connect SOLIDWORKS with 3DEXPERIENCE?

With PLM software as the storage location for all CAD data, your organization can manage all product data efficiently, keeping full control over your data. By full control we mean things such as versioning, change management, access control, property population, lifecycle management, and other product data relevant operations.

As the design team grows, PLM becomes a necessity for efficient design data management. This process is not limited to designing products and storing them into the PLM software, but connecting CAD with PLM is usually a good starting point on the PLM journey. In this blog post, we’ll focus on the functionality of connecting SOLIDWORKS (CAD) to 3DEXPERIENCE (PLM) for the efficient management of design data.

From the designers’ point of view, connecting CAD to PLM streamlines data management by eliminating the need for annual data entries and file transfers. It also enhances data quality and improves design efficiency, leaving more time for the designers to focus on the actual design work. You’ll always have the single source of truth for product data located in the PLM system, available real time to your company throughout all geographies.

From the sales point of view, having PLM access to full real-time design data without the need for CAD software or sending constant requests to the design department proves to be invaluable. The sales team will have a better understanding of the product, better customer service possibilities, understanding of product portfolio status and more accurate forecasting possibilities. Overall, the sales team will become more informed, effective, and responsive towards customers when they have direct access to the product data which creates the backbone of their sales portfolio.

What is the SOLIDWORKS Connector?

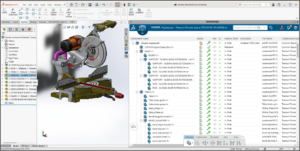

Concisely, it’s a connector client that makes operations in SOLIDWORKS and PLM seamless, whether you use the SOLIDWORKS client or browser-based PLM. Saving data to your PLM platform starts directly from your first sketches and continues throughout the lifecycle of all designed items. The original CAD files are saved to the 3DEXPRIENCE platform when saving from SOLIDWORKS, and the product structure can be maintained in the SOLIDWORKS client or directly in PLM. The process of connecting your SOLIDWORKS client with 3DEXPERIENCE is easy. You simply install the connector once, and from then on, it’s up and running for your daily design work.

What is the SOLIDWORKS Connector User Experience Like?

Basic operations in your CAD system remain the same. All the basic functionality that designers need from SOLIDWORKS is still there, and your SOLIDWORKS setup will be the same as it was before. There’ll be a side panel for PLM operations that you can pop out and assign to a secondary screen, where you can operate in the PLM system without leaving SOLIDWORKS. Wouldn’t it be nice to have one screen for SOLIDWORKS, another for 3DEXPERIENCE, having CAD and PLM available and connected?

The PLM connection enables you to:

- reserve and unreserve files,

- change file maturity,

- create duplicates of design structures to start on the design of a new (but similar) product structure,

- export, and import data packages for manufacturing companies in the ecosystem, and much more.

The properties, materials, features, and other design data input in the SOLIDWORKS client can be mapped to save them to 3DEXPERIENCE, and vice versa. You can fulfill metadata to a product structure in the PLM system via a web-based user interface, and this data will flow back to the CAD properties. All of this means that you’ll always have the latest data without having the risk of locally updated files on a single designer’s computer.

SOLIDWORKS Connector for 3DEXPERIENCE

It might feel overwhelming to start changing your standardized way of working, but when you’re able to reap the benefits, you’ll thank yourself for embarking on the CAD-PLM journey.

The easiest way to get moving is to talk with an expert. So, claim your FREE demo of the SOLIDWORKS 3DEXPERIENCE Connector today!